Tour of the Jeanneau Factory outside of Nantes, France

I’d always wanted to take a look at the Jeanneau production process, which I’d heard was by far the most automated and large operation in the business, and I got the chance to go on July 4th, 2011 (which, unsurprisingly, is not a holiday in France). That week Jeanneau was holding an international distributor meeting and therefore Chris Bent of BAY Yacht Agency was there and we had arranged that he would accompany me on a tour of the facilities while the Jeanneau 57 yacht that I had on order was in the final stages of construction / manufacture / fitting out.

Nantes

Nantes

I’ve been to France many times. At one time I lived and worked in the Alpes-Maritimes region around Antibes. But this was the first time I’d been west of Paris before so I decided to spend the whole weekend in Nantes and play tourist before touring the factory. Thus I departed Germany on Saturday afternoon so that I would get to Nantes in time for a timely check-in at the hotel and chance to partake of the gustatory offerings on the Loire. Taking recent flight experiences into consideration, I was not particularly surprised at the delays on my flights from Frankfurt, Germany via Charles de Gaulle airport in Paris. But I still made it in time for some daylight exploration in the city centre of Nantes.

Normally when I have a piece of paper with a hotel name and a street address and nothing else, I spend ages walking aimlessly around and trying not to look lost before working up the courage to ask for directions; I gather that I’m not alone in this rather irrational behaviour. But this time I took a bus to the centre of town, then randomly chose a direction and soon found myself in the central square (well, circle, to be more precise) and the first exit street that I found happened to be the road on which my hotel was located! I was so surprised that I almost didn’t believe my luck – my first thoughts were that “There must be 2 roads with the same name…”.

I checked into the hotel and dropped off my things in the nice room, located right at the top floor and underneath the slate roof. This location was somewhat sub-optimal for summer conditions, though. I was worried that the room’s superheated air might cause the linen and other combustibles to burst into flame spontaneously. Opening the two windows and departing before I got a stroke was what I ended up doing, and by the time I’d returned from my fine meal the ambient temperature in the room had settled from “Broil” to “Hot”.

Touristic Stuff

Sunday was another sunny, warm and clear day and perfect for me to play tourist and finally let my camera see some shutter action. I’d noted some Jeanneau sailboats with flags close to the main train station on my bus ride the previous day, and also wanted to get an English paperback novel for the return flight. While I didn’t realize it when I went to see the boats, they were expressly there for the dealer meeting and were top-secret-new-models-never-before-shown-in-public. After the book buying (I opted to try reading a Dan Brown thriller) I took a tour through the castle/fortification and walked all around town for several hours in order to work up an appetite for the evening meal, which I’d arranged with Chris.

I’d not brought my cellular phone or notebook and the piece of paper with the time/location for dinner was safely stored back in Frankfurt, but I did wait in the room until around 8pm. I’d asked several times at the front desk whether Chris was in, but was told that he wasn’t and opted to leave and get some food by myself – fortunately Chris, his wife, Eric (the proprietor of Bay Yacht Agency) and Douglass, his companion were at the front desk and asking for me. Just 50 yards away was La Cigale, our restaurant for the evening. After a great meal, we retired for the evening in preparation for the factory tour the next day.

Factory

The ladies didn’t join Chris, Alex and Jeff (Jorgenson, from Jeanneau USA) to head off to Les Herbiers from Nantes the next morning. Fortunately we were headed out of town and the heavy inbound traffic didn’t affect us at all. We arrived at the Jeanneau factory after just a short detour or two (despite on board GPS navigation) and, after an obligatory coffee, proceeded to begin our tour of the major halls in the factory. While I could use my camera in most places in the factory, the injection moulding hull construction hall and the milling machine were off limits to paparazzi such as myself

The ladies didn’t join Chris, Alex and Jeff (Jorgenson, from Jeanneau USA) to head off to Les Herbiers from Nantes the next morning. Fortunately we were headed out of town and the heavy inbound traffic didn’t affect us at all. We arrived at the Jeanneau factory after just a short detour or two (despite on board GPS navigation) and, after an obligatory coffee, proceeded to begin our tour of the major halls in the factory. While I could use my camera in most places in the factory, the injection moulding hull construction hall and the milling machine were off limits to paparazzi such as myself

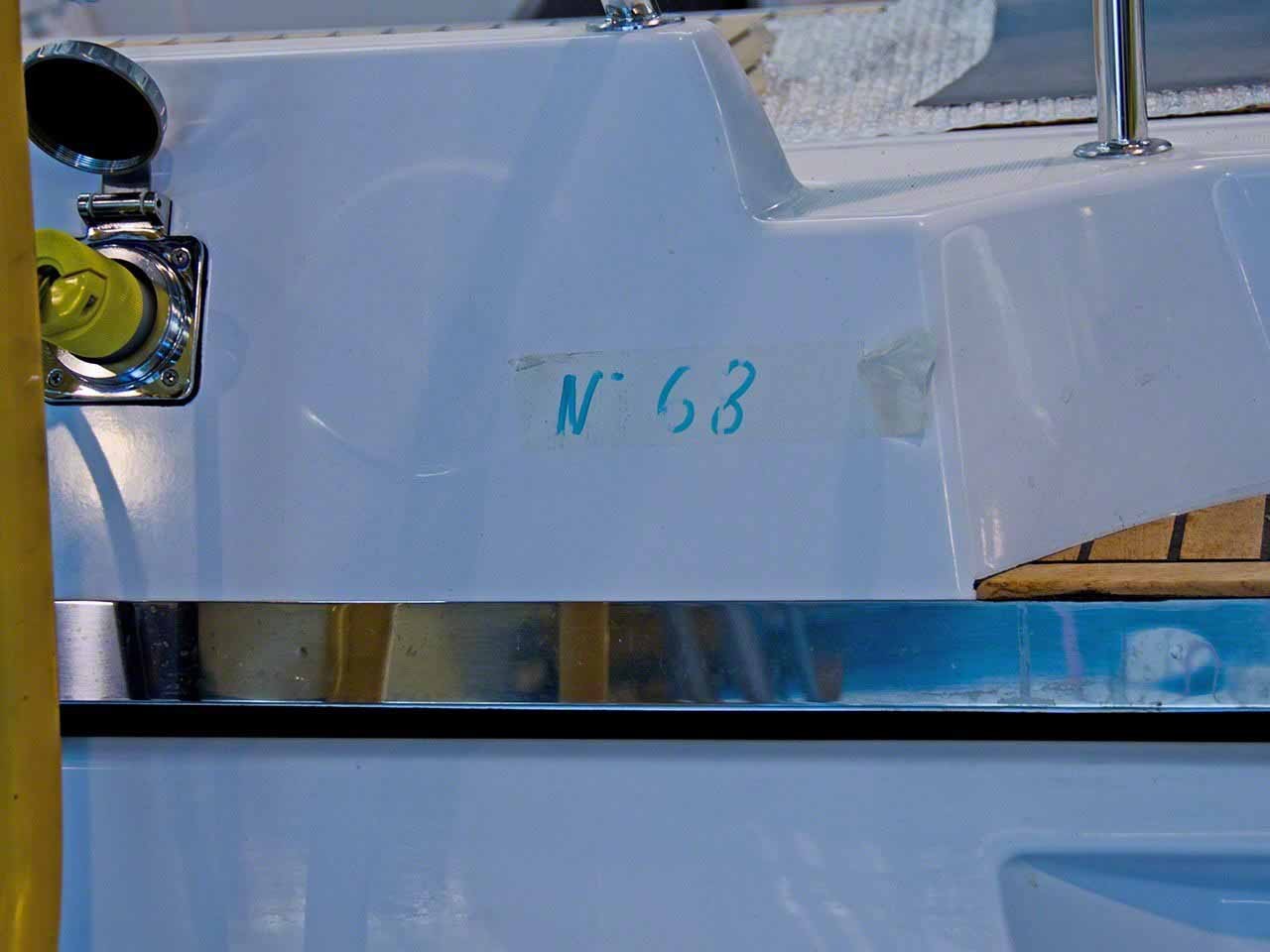

But on the upside, I was informed that the future Zanshin was hull Nº 68 and that it was in the final stages of production and we’d be visiting her towards the end of the tour.

Laying Up

The tour began in the hall where the hulls were laid up in the moulds and it was very impressive to see how they approached making the huge one-piece hull for the Jeanneau 57. The resin has a special chemical dye that reacts with the glass mats and thus makes it easy to see which parts of a layer might be resin starved. The individual glass mats are pre-cut and numbered and I was surprised how small some of the individual pieces were, they were about the size of my hand. The mould for the Jeanneau 57 is a two-part one, as the shapes of the hull and the size of the hull make a one piece mould difficult if not impossible to construct.

After that building we visited the big milling machine, which fills most of another hall. I’d worked with 3D milling machines before, but none even approaching the size of this behemoth – the whole deck of a Jeanneau 57 easily fit into the hall and the mill moved on tracks from above and would, with pinpoint accuracy, drill holes and mill out hatch and winch openings. All that in a matter of 2.5 hours for a whole Jeanneau 57; the savings compared to doing this manually are huge and no human can be that accurate and consistent. Again, no pictures were permitted in this area.

Production Lines

The production lines for the boats was the next stop on the tour and the Jeanneau 57 line was at the far left side of the building, with numerous other production lines for sailboats and powerboats going alongside in parallel. I didn’t see how many stations the other lines had, but despite the length of the building there was space for only 3 stations for the Jeanneau 57 due to the size of the boat. The building itself was immaculate and I liked the touch of having enclosed cabins for each line for workers to rest – and smoke. The Jeanneau 57 production line started with a hull that was being filled with equipment underneath the floorboards and this allowed us to walk into the hull and get an idea of how massive and voluminous it really is and I was, and remain, duly impressed. The pictures below give a sense of scale but I’d recommend any future boat purchasers to get a factory tour (be it Jeanneau or any other manufacturer) and to get a feel for the sizes, volumes and amount of effort involved in putting a sailboat together.

Two years earlier I’d flown to the U.K. boat show in Southampton and spent 2 days going through all the nooks and crannies on their demonstration boat so I knew what I was looking at.