Getting an invisible edge

Sharpening this Ka-Bar blade will make it much easier and safer to use. Putting a keen edge on a knife blade isn’t difficult but does take a bit of practice and effort. One needs to keep in mind that knife sharpening is old profession. It takes years to become a true master – even the Japanese Katana swords needed days or weeks of manual polishing to reach their level of sharpness. Most knife edges coming straight from the factory have a good grind angle but only a marginally acceptable edge. transforming a rough grind to a keen edge takes time and effort and skill, which costs money and commercial enterprises need to make a profit. This results in factory edges that are acceptable, but not necessarily superior.

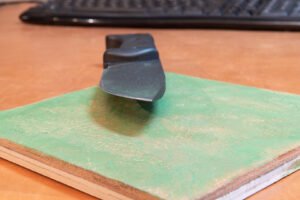

This Becker Ka-Bar Companion BK2 was just sharp enough to pass a carefully administered paper cut test. Barely. The pictures show that the factory sharpening left some pretty deep furrows in the edge.

Time to soak my waterstones and sharpen a Ka-Bar blade. There was no need to change the blade angle, just finish off the sharpening process.

After using a rough water stone, then a 3000-grit Japanese water stone and finally a 10000-grit water stone and a bit of stropping on a leather with green chromium oxide paste, the edge looks a lot nicer and the blade slices through paper with no effort at all. The angle is still high, as is necessary for an all-around knife. This angle of over 20° will work for hacking wood and keep sharper longer than had I made a finer angle as would be seen on a fileting knife. And my straight-edge razor blades need an even finer angle than that, but are many times more fragile.